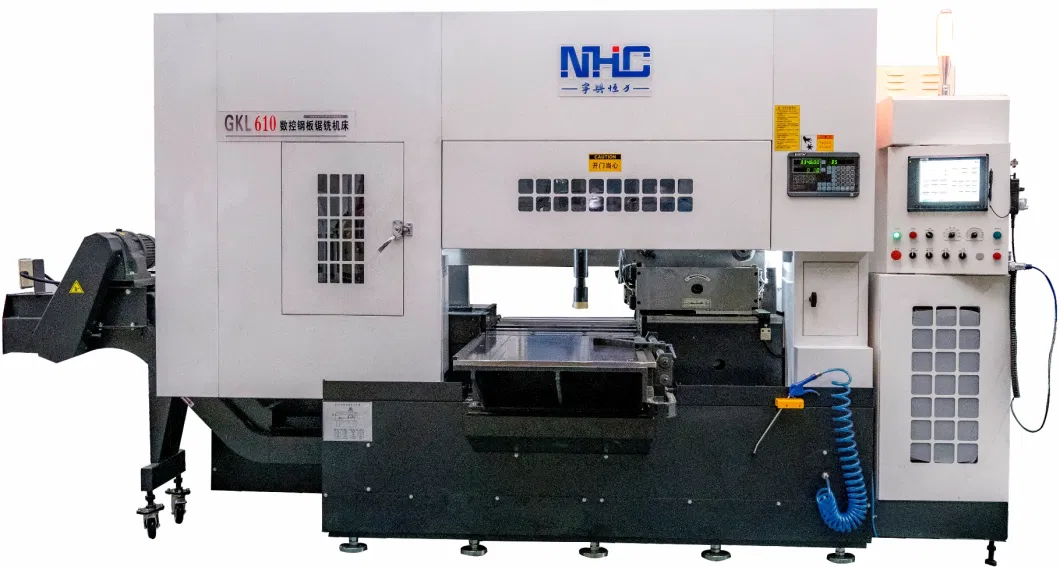

Batch of Small Mechanical Parts Die Blank Material Circular Saw Blade Milling Cutting Table Panel Band Router CNC Machine Tools Sawing Machine for GKL610

Overview Batch of Small Mechanical Parts Die Blank Material Circular Saw Blade Milling Cutting Table Panel Band Router C

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | GKL610 |

| Certification | CE |

| Condition | New |

| Cooling Mode | Oil and Mist Spray Cooling |

| Machine Weight | 8 Tons |

| Revolve Speed | 50-120 r / min, Stepless Speed Change |

| Clamp Mode | Horizontal and Vertical |

| Cut Side Perpendicularity | <=0.3 mm / 100 mm |

| Cut Side Straightness | <=0.12 mm / 650 mm |

| Mode of cutting | Manual blanking |

| Saw length tolerance | ±0.2mm |

| Cut Range | W:50-650,T:20-100 mm |

| Blade Size | φ425 |

| Plate Length | <=3000mm |

| Cut Length | >=10 mm |

| Cut Feed Motor Power | 4.3 kW |

| Feeding Motor Power | 1.26kW |

| Spindle Motor Power | 15 kW |

| Transport Package | Main Engine and Wooden Case |

| Specification | 4500*3900*2300mm |

| Trademark | Ningshing |

| Origin | China |

Product Description

Batch of Small Mechanical Parts Die Blank Material Circular Saw Blade Milling Cutting Table Panel Band Router CNC Machine Tools Sawing Machine for GKL610

Used for small-sized mechanical parts and precision blanking of mold blanks.Features:

>The main structural parts are made of high-grade castings, and the machine tool has good rigidity;

>The guide rail adopts a rolling-sliding composite structure, and the machine tool runs smoothly;

>The creative design of the gear box ensures zero clearance of the main shaft output and prolongs the service life of the circular saw blade:

>Both feeding and cutting feed are controlled by servo motor and CNC system to ensure the precision of sawing length;

>The workpiece clamping adopts upper pressing and side clamping bi-directionally, and the clamping is safe and secure.

Reliable:

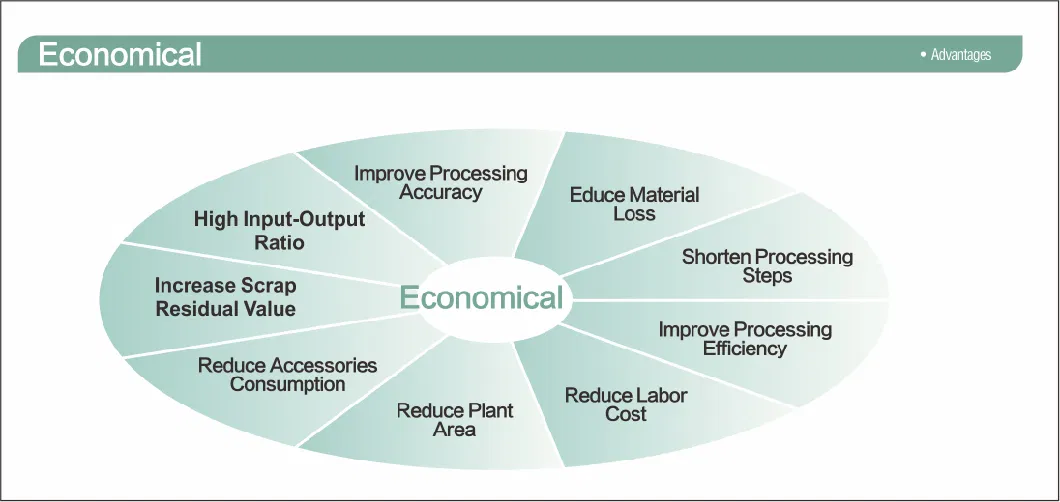

Applicative:

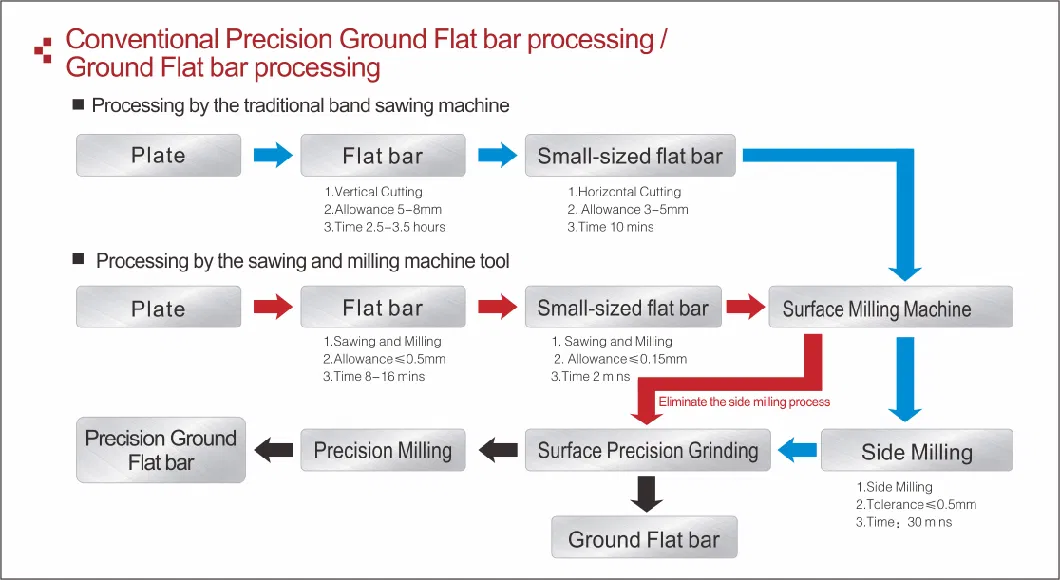

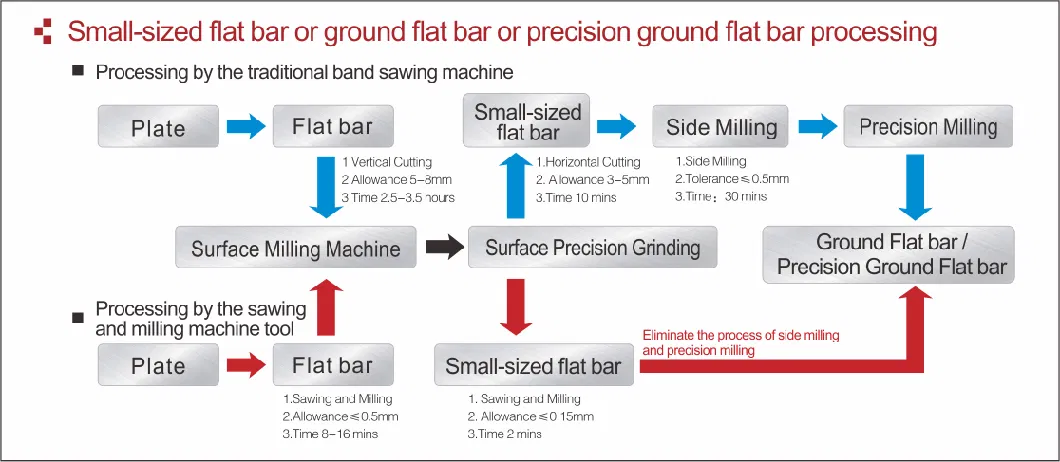

(1)Wide application field:In the field of metal processing, the traditional cutting and rough milling are replaced by an efficient and accurate "saw milling" method.(2)Multi-variety processing:Non-ferrous metals: copper, aluminum and its alloys;Ferrous metal: carbon steel, die steel, stainless steel, alloy structural steel, spring steel, wear-resistant steel, etc.

(3)Customized:According to customer needs, can be tailored.

Why us?

1# Over 10 years Independent R&D2# National Innovation Patent Certificate3# Annual sales volume in China has exceeded 200 sets4# Used for cutting Steel Plate, Flat Bar, Ground Flat and P-plate, etc5# Fast sawing, high efficiency, less material wastage and free side milling6# Have been serving Baosteel, Nangang, Xiangtan (XISC), TISCO and other prime mills in China. 7# Serving industries e.g. Engineering Machinery, Mold Base, Wind Power, etc.

Ningshing Precision Machinery began in 1992. We devote oneself to providing One-Stop Solutions to our customers on Tool Steel, Die Steel, Alloy Steel, Mold Base, Machining Parts, CNC Machine.

Main ProductsView more products, you can click product key words.

| Main Products | ||

| Steel Flat | Steel Plate | Die Steel |

| Plastic Mold Steel | Alloy Steel | Pre-machined Flat |

| Die Casting Die | Mold Base | Aluminum Die |

Related Products

-

![PE OPP Film High Speed Slitting Rewinding Machine Max. Working Speed 400m/Min]()

PE OPP Film High Speed Slitting Rewinding Machine Max. Working Speed 400m/Min

-

![Quality Automatic A4 Paper Cutting Machinery/A4 Paper Sheeting Machine with Automatic Trimming Roll to Sheet Cross Cutting Machine]()

Quality Automatic A4 Paper Cutting Machinery/A4 Paper Sheeting Machine with Automatic Trimming Roll to Sheet Cross Cutting Machine

-

![Woven Fabric Roll to Sheet Cutting Machine]()

Woven Fabric Roll to Sheet Cutting Machine

-

![Cold Laminating Cardpaper+Corrugated Paper Koten Manual Laminator Flute Lamination Machine]()

Cold Laminating Cardpaper+Corrugated Paper Koten Manual Laminator Flute Lamination Machine