Flexographic Aluminum Foil Plastic Paper Cup Film Label Roll Cold Stamping Laminating Lamination Die Cutting Cutter Machine

Product Description Middle Speed Paper Cup Forming Machine: Reliability:Smart middle speed paper cup forming machine is

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | YG-16 |

| Logo Printing | With Logo Printing |

| Certification | CE |

| Customized | Customized |

| Condition | New |

| After-sales Service | Video Technical Support |

| Maximum Web Width | 180mm |

| Type | Punching Machine |

| Keyword | Paper Cup Making Machine |

| Material | 150-300GSM Paper Coated PE Film |

| Paper Specification | 150-250g Single PE Paper |

| Computerized | Automatic Panel Contral |

| Controller | PLC |

| Usage | Packing Paper Machine, Paper Cup Machine |

| Cup Size | 4-16oz |

| Weight | 3660kgs |

| Running Speed | 55-70PCS/Min |

| Total Power | 3.5kw |

| Electrical Specifications | 220V/50Hz |

| Air Use | 0.5-0.8MPa |

| Transport Package | Wooden |

| Specification | 2800*1400*1700mm |

| Trademark | Yugong |

| Origin | China |

| HS Code | 8441309000 |

| Production Capacity | 500sets/Month |

Product Description

Product Description

Middle Speed Paper Cup Forming Machine:

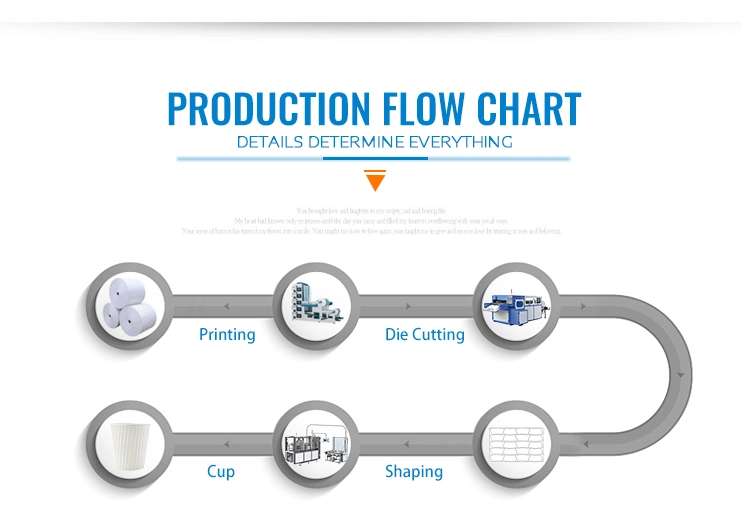

Reliability:Smart middle speed paper cup forming machine is provided with advantages of high performance,high efficiency and high quality.The overall steel plate machine body and oil-spraying lubrication system ensures normal and stable long-term operation of the equipment.

High Efficiency and Energy Conservation:Advanced high-precision cylindrical cam driving unit working with gear drive system make sure the precisely working of every station.Bottom paper feeding controlled by servo tracking system,and raw material paper can be saved effectively.

Foreign technical and Made in China:Paper bottom heating system(Switzerland Leister)uses 2 steps flameless heating.Every step in production is monitored by photocell (Japan Omron)and be reported.

User-friendly design:The function of machine is controlled by human-computer interface and PLC system.Manual operation can be replaced by automatic paper cup counting and collection table with appropriate setting.

| Cup size | 6~16oz(outside diameter ofa cup 60-90mm,outside diameter of bottom 50~70mm,height of cup 50~135mm,depth of bottom 5~10mm) |

| Rated speed | 90-110pcs/min |

| Main motor power | 2.2KW |

| Electro thermal power | 8.6/13.2KW |

| Air source | 0.6m/min;0.6MPa customer-owned |

| Applical base paper | 190~350g/(single or double PE coating paper) |

| Weight | 3.8T |

| Main size | 2700*1500*1800mm |

| Paper cup collector size | 1150*850*2000mm |

| Actual power consumption | 7.5KW |

| Remark | The paper thickness error margin is ±0.05mm for the same set of mould |

Packaging & Shipping

1. Packaging:

Packed by standard import & export wooden cases or carton boxes.

2. Shipping:

By logistics; by automobile; by train; by shipping; by air etc.

Company Information

Our Services

1.We have more than15 years manufacture and export experience.

2.Exporting to all over the world,win high reputation among customers.

3.CE, ISO 9001 and Strict Production Guideline to guarantee the high quality of our products.

4.Near the Qingdao port convenient for exporting.

5.Customer service staff 24 hours online,offer free technical support.

6.Factory and Competitive Price we offer.

7.Strong Research & Development technical team.

8.Various machinery to meet all your needs at our factory.

9.Engineers are available to guide the installation and take care of other problems.

10.We offer OEM&ODM service to meet all your requirements.

FAQ

1

Q:Are you trading company or manufacturer?

A:We are original equipment manufacturer.

2

Q:How long is your delivery time?

A:It is according to the model and quantity.Generally it is 3-5 days if the product are in stock.It will be 15-30 days if you want to customize the product.

3

Q:Do you provide samples? ls it free or extra?

A:Yes,we could offer you the sample.But it's not free.

You need to pay for the sample and the cost of freight.

4

Q:What is your terms of payment?

A:We accept T/T,Westerm Union,Money Gram,Paypal,etc.

Payment

Related Products

-

![Jumbo Paper Roll Slitting Rewinding Machine Price]()

Jumbo Paper Roll Slitting Rewinding Machine Price

-

![Automatic A4 Copy Paper Production Line Roll to Sheet Cutter Paper Making Machine A2 A3 A4 Paper Roll to Sheet Cross Cutting Machine with Wrapping Machine]()

Automatic A4 Copy Paper Production Line Roll to Sheet Cutter Paper Making Machine A2 A3 A4 Paper Roll to Sheet Cross Cutting Machine with Wrapping Machine

-

![China Factory Wholesale Price New Automatic Cutting BOPP PE PVC Film Foil Paper Fabric Roll Cutter Slit Slitter Rewinder Slitting Rewinding Making Machine]()

China Factory Wholesale Price New Automatic Cutting BOPP PE PVC Film Foil Paper Fabric Roll Cutter Slit Slitter Rewinder Slitting Rewinding Making Machine

-

![Automatic Metal Sheet Plate Cross Cutting Machine]()

Automatic Metal Sheet Plate Cross Cutting Machine