Fully Automatic Big Jumbo Roll Paper Slitting and Rewinding Machine for Paper Non Woven Aluminum Foil Label PVC with Unwinding 1800mm

Overview Product Description KFQ-1800 Paper Slitting And Rewinding Machine KFQ series model slitting and rewinding machi

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | KFQ-1800 |

| Packaging | Case |

| Classification | Slitting Rewinding Machine |

| Applicable Process | Process Materials |

| Suitable Substrates | Paper, Film, Aluminum Foil, Pet, PVC |

| Packaging Material | Wood |

| Max Rewinding Diameter | 1300mm |

| Motor | Servo Motor |

| Min. Width of Slitting | 40mm |

| Advantage | Multiple Function |

| Waste Edge | Blowing out Device |

| Winding Method | Central Surface Rewinding |

| Web Guide | Ultrasonic Sensor/CCD |

| Rewinding Shafts | a,B Air Shafts |

| Weight | 15000 Kgs |

| Power | 60kw |

| Counting Method | Automatic |

| Materials Available | Paper, Bill Paper, Non Wove,Sticker, PVC |

| Max Unwinding Width | 1800mm |

| Max Unwinding Diameter | 1700mm |

| Speed | 600m/Min |

| Transport Package | Wooden Case |

| Specification | 8500*3750*2700mm |

| Trademark | Gaobao |

| Origin | China |

| HS Code | 84411000 |

| Production Capacity | 50 |

Product Description

Product Description

KFQ-1800 Paper Slitting And Rewinding Machine

KFQ series model slitting and rewinding machine is our Leader model of Gaobao(Hightop) Machinery. It is the most automated, fastest and widely used of all our slitting and rewinding machines. It is equipped with 3 pole main servo motors, Automatic edge positioning correction system, Siemens PLC and other internationally renowned brands of electrical control systems. The stable running speed reaches 600 meters per minute, which can perfectly slit and rewind 40-800 gsm paper jumbo rolls into narrow width rolls

- The machine adopts synchronous control of three servo motors, automatic constant tension structure, and center surface rewind;

- The machine adopts frequency inverter to keep running smoothly during acceleration

- Automatic meter counting, alarm and other functions;

- Winding adopts A, B air shaft structure, easy loading and unloading

- Unwinding adopts static analog ultrasonic

- Round knife slitting waste edge automatic discharge device

- Hydraulic automatic shaft-less feeding frame structure

KFQ series is particularly suitable for processing webs with a width of 1300mm,1600mm,1800mm,2000mm. Therefore, it is used in a large number of paper mills, paper converting plants, and roll slitting service providers. Customer can choose suitable width of machines based on production and materials specifications. In addition, many paper product manufacturers such as paper bags, paper cups, paper tubes, etc. also need to use KFQ slitter rewinder. It is widely used in the field of printing and paper product packaging.

Loading jumbo rolls in our machine, setting up the knife position based on slitting width you want to get. Then you will get several finished roll slitting and rewinding with different sizes or same sizes then move it out for production after.

| Model | KFQ-1300 | KFQ-1600 | KFQ-1800 | KFQ-2000 |

| Max Width of Unwinding | 1300mm | 1600mm | 1800mm | 2000mm |

| Max Diameter of Unwinding | 1700mm | 1700mm | 1700mm | 1700mm |

| Max Diameter of Rewinding | 1300mm | 1300mm | 1300mm | 1300mm |

| Min. Width of Slitting | 40mm | 40mm | 40mm | 40mm |

| Speed of Slitting | 600 m/min | 600m/min | 600m/min | 600m/min |

| Grammage | 40-800 GSM | 40-800 GSM | 40-800GSM | 40-800GSM |

| Power Input | 380V 50HZ 56KW | 380V 50HZ 56KW | 380V 50HZ 60KW | 380V 50HZ 67KW |

| Dimension | 8500*3250*2700mm | 8500*3550*2700mm | 8500*3750*2700mm | 8500*4050*2700mm |

| Total Weight | 13000KGS | 14000KGS | 15000KGS | 1700KGS |

Machine Photos

Machine Details Introduction Unwinding stand: KFQ paper slitter rewinder machine adopt the hydraulic control unwinding stand,which can easily pick up 2000kg-3000kg weight and 1700mm diameter jumbo rolls. There are different type of unwinding structure match with different standard of weight holding requests, light structure unwinding and heavy structure unwinding .

Our machine design is very flexible for meet clients' material specifications and requests.For example,customer has paper rolls with different core size like 3 inch 5 inch 6 inch or other size and need to change core in the machine each time and spend more time if sizes changes too much often.Conic Structure is able to solve this problem, contact sales for getting more details. Contact our sales for getting more details. Magnetic Powder Tension Control

About of the unwinding tension control,we have three options,magnetic powder brake,pneumatic brake,and servo motors depend on material weight needed to be feeded. If you want to know which type tension controlling system is better for your material,please contact with our sales teams.Slitting knives

The slitting knives is enough strong to hold knives and avoid trembling during machine running. Therefore, the cutting accuracy is very high.One end of the shaft is fixed, and the other end is rotatable. This design makes it very easy to replace the slitting knives.The slitting knife is made of high-speed alloy steel. It has the characteristics of high precision and durability.Bottom Knife

whole set of slitting device is consist of 2 parts, up with round knife and bottom knife down sideRewinding Unit

Rewinding shafts adopt A,B shaft. Two sets motors drive rewinding shafts and output reasonable tension to get high quality finished rewinding rolls. Cutting surface is smooth and no wrinkles.Finished rolls can be automatic unloaded to save operating labors.Rewinding Unit

Rewinding shafts adopt A,B shaft. Two sets motors drive rewinding shafts and output reasonable tension to get high quality finished rewinding rolls. Cutting surface is smooth and no wrinkles.Finished rolls can be automatic unloaded to save operating labors.

-----------------------------------------------------------Know More About Gaobao/Hightop------------------------------------------------------------

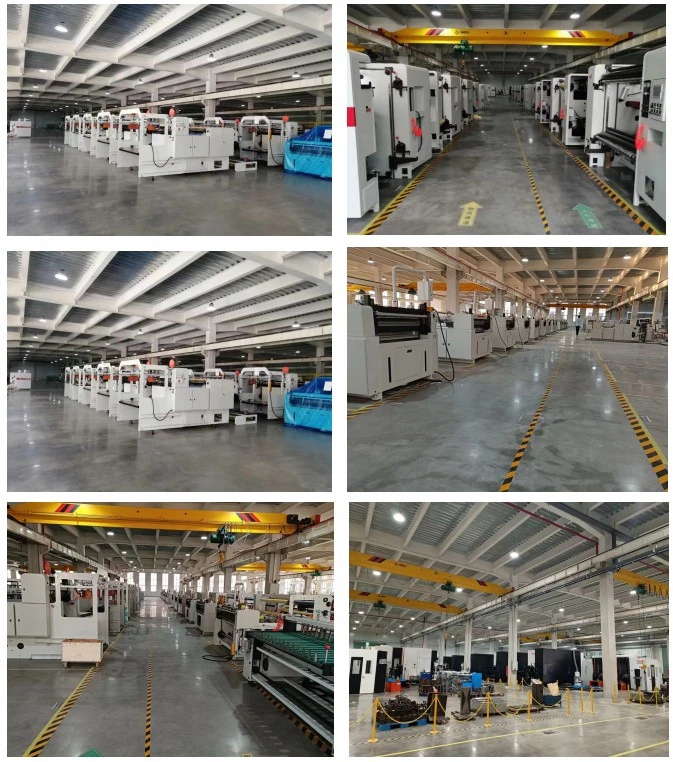

Our Factory

Exhibition

Machine will be well packed in wooden case each part and load into containers. The machine will be properly fixed to ensure that the machine will not move and collide during transportation, and it will be kept dry to adapt to the sea weather conditions.

FQA:

Why you need a set paper jumbo roll slitter rewinder machine?

Answer: If you are director and owner of the paper converting companies,printing house or paper roll processing factories,you must want to process more large width jumbo roll. The KFQ series paper slitter rewinder machine is an ideal equipment to reach the requirement. The gantry structure ensure that machine can stable slit and rewind more than 2000mm width paper jumbo rolls.

What are the advantages of the unwinding stand in the KFQ series paper slitting rewinding machine?Answer:Our unwinding stand itself weighs more than12 tons. When it is loaded with jumbo paper rolls and speed reach maximum, it can still remain very stable. The arms in the unwinding stand are controlled by hydraulic cylinders,which have enough power to pick up 3000kgs even 5000kgs weight paper rolls and 1700mm diameter rolls.

Pre Sales Service-----------------------------------------

How to get in touch with us?

Direct to the company: Building 9, No.3-11, Hairun Road, Binhai Development Zone, Pingyang County, Wenzhou City, Zhejiang Province, China.

How to answer technical guidance?

For some customers who need non-standard equipment, we will communicate with the company's relevant technical personnel according to the customer's specific requirements, taking into account the technical feasibility and production costs, and give customers solutions.

How to recommend products?

We can provide non-standard equipment production and new product development services according to customer requirements. According to the customer's requirement to be produced, the purpose of the product to be purchased, the environment, the purchase volume and other related conditions, we will recommend several cost-effective products for the customer to choose.

About payment

After signing the contract, 30% of the total payment will be paid in advance, and the factory will accept the payment and pay the full amount of the machine for delivery.

About delivery timeAbout 30-45 working days after receiving the deposit (non-standard machine), the factory will re-decide whether to change the delivery date when the order is confirmed. The standard machine is generally within 30 working days after receiving the deposit.

Order tracking

After the customer places an order, our company will send professional personnel to track the order and regularly report the production progress to the customer.

Product testingDuring the production process, our company will adopt strict inspection process to ensure product quality. Through internal inspection, we ensure that the components produced by our company meet the technical requirements; through external inspection, we ensure that the components produced by our company are not subject to quality problems; and then pass the whole machine inspection to ensure that the mechanical equipment meets the technical production requirements .

Product packagingBefore the product is shipped, it will be packed in a strict vacuum plus bottom tray (wooden tray or steel tray)

Product TransportationProducts are generally shipped from Ningbo Port, China to the destination port by sea.

After Sales Service

-------------------------------------------------01. Shelf life/warranty period of the productThe product warranty period is generally one year, and our company provides lifetime maintenance services. If the machine has quality problems, our company will help the customer to solve it through the following ways: a. Send spare parts to the customer. b. Remotely assist customers in maintenance. c. Notify our agent company to send personnel to the customer's factory for maintenance. d. Our company directly dispatches relevant personnel to the customer's factory for maintenance.02. About transportation damageIn the process of product transportation, if product damage occurs, it is determined that our product packaging and reinforcement work is not in place, and our company will bear the corresponding losses.03. About machine maintenanceWe will contact customers on a regular basis on how to maintain and maintain the machine. For domestic customers, we will have a master to provide on-site service.04. Problems during useIf there is any problem in the process of using the product, the customer can directly call or send an email to our after-sales department (24-hour hotline). The personnel of our department will respond immediately and make a decision on the response measures within 24 hours.

Related Products

-

![High Speed Plastic Film Nylon Paper Slitter and Rewinder PLC Control]()

High Speed Plastic Film Nylon Paper Slitter and Rewinder PLC Control

-

![Dakiou Paper Cup Roll to Sheet Die Cutting Machine]()

Dakiou Paper Cup Roll to Sheet Die Cutting Machine

-

![Precise Aluminum Foil Plastic Paper Cup Film Label Roll Cold Stamping Laminating Die Cutter Machine]()

Precise Aluminum Foil Plastic Paper Cup Film Label Roll Cold Stamping Laminating Die Cutter Machine

-

![Rbt CNC Milling/Tapping/Drilling/Cutting Machine for Die Casting Metal Aluminum Alloy Mechanical Auto Bicycle Machinery Precision Hardware Mold Aluminum Parts]()

Rbt CNC Milling/Tapping/Drilling/Cutting Machine for Die Casting Metal Aluminum Alloy Mechanical Auto Bicycle Machinery Precision Hardware Mold Aluminum Parts